Kanda simbi kabati mabara, pfeka zvikamu zvemarara kune simba tira

1. Kukanda nzira: Shell muforoma nemazvo kukanda

2. Sirivheri giredhi: GX130CrSi29 (1.4777) (Zvakare inogona kuve sekudikanwa kwako)

3.Kutenderera Kushivirira kwesimbi: DIN EN ISO 8062-3 giredhi DCTG8

4. Geometrical Kushivirira kwesimbi: DIN EN ISO 8062 - giredhi GCTG 5

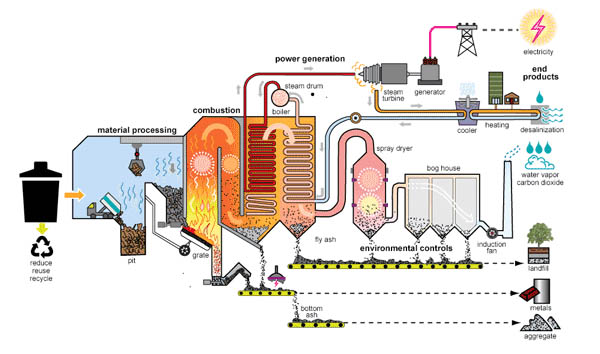

5. Kushanda: Waste kune magetsi kupisa miti.

Kurasa marara ikozvino rave dambudziko rakakomba pasi rese. Tsvina kune simba ndiyo kurapwa kunonzwisisika parizvino. Mumakore achangopfuura, nyika zhinji dzine simba rakasimba rehupfumi dzakatanga kutarisisa iyi pfungwa. Mari yakawanda yakaiswa mukuvakwa kwemarara emagetsi emagetsi. Izvi hazvina chete kuunza kuvandudzika kukuru kunharaunda yedu. Panguva imwecheteyo, zvakatiunzira mabhenefiti makuru ehupfumi.

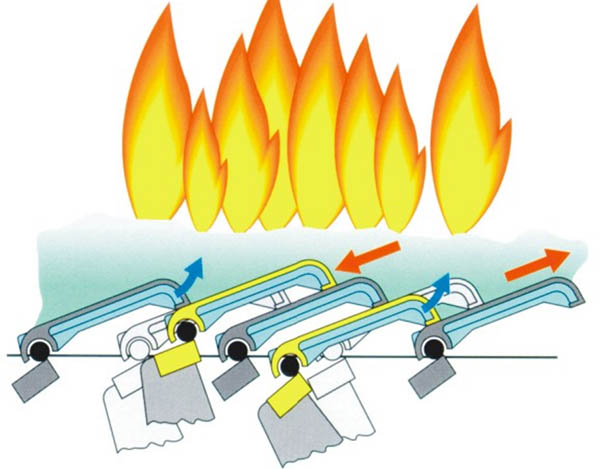

Sezvinoratidzwa mumufananidzo, mabhawa emabhata anoita basa rakakosha mukupisa marara. Mumamiriro ekushisa akakwirira uye nharaunda yakaoma, Yakaderera mhando kabati inokanganisa zvakanyanya kushanda kwemarara kupisa, uye hupenyu hwayo hwebasa ipfupi. Iwe unofanirwa kuzvitsiva kazhinji.

Nekudaro, nemakore anopfuura gumi uchikanda ruzivo, tinogona kugadzirisa matambudziko ako.

Simbi Giredhi isu tinowanzo shandisa. (Inogona zvakare kuve sekuda kwako.)

Chemical kuumbwa% yesimbi GX130CrSi29 (1.4777): EN 10295-2002

|

C |

Si |

Mn |

Ni |

P |

S |

Cr |

Mo |

|

1.2 - 1.4 |

1 - 2.5 |

0.5 - 1 |

max 1 |

max 0.035 |

max 0.03 |

27 - 30 |

max 0.5 |

Chemical kuumbwa% yesimbi GX40CrNiSi27-4 (1.4823): EN 10295-2002

|

C |

Si |

Mn |

Ni |

P |

S |

Cr |

Mo |

|

0.3 - 0.5 |

1 - 2.5 |

max 1.5 |

3 - 6 |

max 0.04 |

max 0.03 |

25 - 28 |

max 0.5 |

Chemical kuumbwa% yesimbi GX40CrNiSi25-20 (1.4848): EN 10295-2002

|

C |

Si |

Mn |

Ni |

P |

S |

Cr |

Mo |

|

0.3 - 0.5 |

1 - 2.5 |

max 2 |

19 - 22 |

max 0.04 |

max 0.03 |

24 - 27 |

max 0.5 |

Chemical kuumbwa% yesimbi GX40CrNiSi25-12 (1.4837): EN 10295-2002

|

C |

Si |

Mn |

Ni |

P |

S |

Cr |

Mo |

|

0.3 - 0.5 |

1 - 2.5 |

max 2 |

11 - 14 |

max 0.04 |

max 0.03 |

24 - 27 |

max 0.5 |

| Mechanical zvivakwa (ASTM A297 Giredhi HH) 1.4837 | UTS: Min 75 Ksi / 515 Mpa |

| YS: Min 35 Ksi / 240 Mpa | |

| Kukwirisa: mu 2 mu: Min 10% | |

| Kuoma: Min 200 BHN (3 nzvimbo pane speciment) " | |

| Microstructure / Metallography | Zvikurukuru chimiro cheAustenitic chine macarbides akapararira |

| SoundnessTest / X-ray kana UT | RT paASM E446 Chikamu II |

| UT paASMM A609 Chikamu II | |

| NDT / LPI kana MPI | MPI sekuenderana neASTM E709 / E125 LEVEL II |

| LPI maererano neASMM E165 Level II " | |

| Yekupedzisira Yekutarisa Kuongorora | ASTM A802 Chikamu II |

| Pasuru | Iron kesi kana Wooden kesi. |

Musika Wedu Mukuru Ari

OEMs uye mainjiniya makambani

Tsvina kune Simba magetsi

Makambani anoshanda

Biomass zvikamu

Magetsi emagetsi emarasha

Makambani ebasa ekuchengetedza mashandiro

Mhando dzakasiyana dzeOEM kabati bar

Yakapedzwa zvakanaka kabati mabara

Yakakura Matanho Uye Yakaomarara Hunhu Kudzora Is Nei uchizosarudza isu

Kune mimwe mibvunzo kana yehunyanzvi mibvunzo, ndapota nyorera XTJ Service Team. Isu tichapa iyo inonzwisisika mhinduro yehunyanzvi uye yakanyanya kunaka chitaurwa zvinoenderana nechigadzirwa chako.