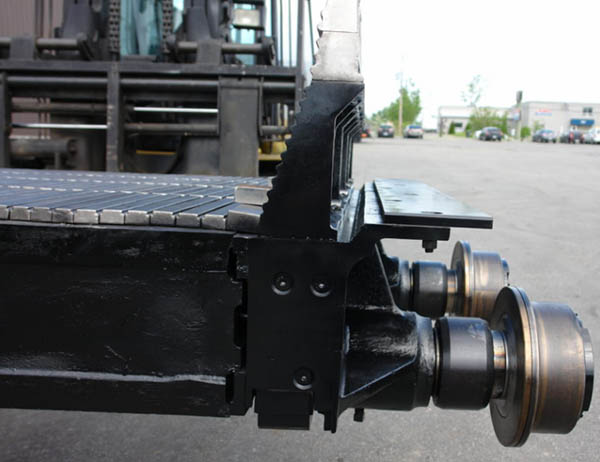

Grate bhaa uye Kurutivi madziro, Wear Zvikamu pane nhovo mota uye sinter / pellet mota

1. Kukanda nzira: Shell muforoma nemazvo kukanda

2. Simbi yegiredhi: 1.4777 1.4823 1.4837 1.4848

3.Kutenderera Kushivirira kwesimbi: DIN EN ISO 8062-3 giredhi DCTG8

4. Geometrical Kushivirira kwesimbi: DIN EN ISO 8062 - giredhi GCTG 5

5. Kushanda: Pfeka Zvikamu pamota dzemotokari uye sinter mota.

Isu tiri vanotungamira vatengesi kune pallet mota uye sinter mota vagadziri uye hombe simbi zvigayo. With anopfuura makore gumi 'Kudzingwa ruzivo, izvi nemishonga zvikamu zvinoberekwa nesu nguva dzose zvakanaka michini pfuma uye akakwana kukanda pamusoro. Tekinoroji yevakakura yakanyatso kudzora yedu yekugadzira mutengo, kuitira kuti iwe ugone kuhodha-yakachipa zvigadzirwa kubva kwatiri. Mumakore achangopfuura, kuwedzera kwehuwandu hwekugadzira kwakasimudzirawo zuva rako rekutakura.

Simbi Giredhi isu tinowanzo shandisa. Inogona zvakare kuve sekuda kwako.

Chemical kuumbwa% yesimbi GX130CrSi29 (1.4777): EN 10295-2002

|

C |

Si |

Mn |

Ni |

P |

S |

Cr |

Mo |

|

1.2 - 1.4 |

1 - 2.5 |

0.5 - 1 |

max 1 |

max 0.035 |

max 0.03 |

27 - 30 |

max 0.5 |

Chemical kuumbwa% yesimbi GX40CrNiSi27-4 (1.4823): EN 10295-2002

|

C |

Si |

Mn |

Ni |

P |

S |

Cr |

Mo |

|

0.3 - 0.5 |

1 - 2.5 |

max 1.5 |

3 - 6 |

max 0.04 |

max 0.03 |

25 - 28 |

max 0.5 |

Chemical kuumbwa% yesimbi GX40CrNiSi25-20 (1.4848): EN 10295-2002

|

C |

Si |

Mn |

Ni |

P |

S |

Cr |

Mo |

|

0.3 - 0.5 |

1 - 2.5 |

max 2 |

19 - 22 |

max 0.04 |

max 0.03 |

24 - 27 |

max 0.5 |

Chemical kuumbwa% yesimbi GX40CrNiSi25-12 (1.4837): EN 10295-2002

|

C |

Si |

Mn |

Ni |

P |

S |

Cr |

Mo |

|

0.3 - 0.5 |

1 - 2.5 |

max 2 |

11 - 14 |

max 0.04 |

max 0.03 |

24 - 27 |

max 0.5 |

| Mechanical zvivakwa (ASTM A297 Giredhi HH) 1.4837 | UTS: Min 75 Ksi / 515 Mpa |

| YS: Min 35 Ksi / 240 Mpa | |

| Kukwirisa: mu 2 mu: Min 10% | |

| Kuoma: Min 200 BHN (3 nzvimbo pane speciment) " | |

| Microstructure / Metallography | Zvikurukuru chimiro cheAustenitic chine macarbides akapararira |

| SoundnessTest / X-ray kana UT | RT paASM E446 Chikamu II |

| UT paASMM A609 Chikamu II | |

| NDT / LPI kana MPI | MPI sekuenderana neASTM E709 / E125 LEVEL II |

| LPI maererano neASMM E165 Level II " | |

| Yekupedzisira Yekutarisa Kuongorora | ASTM A802 Chikamu II |

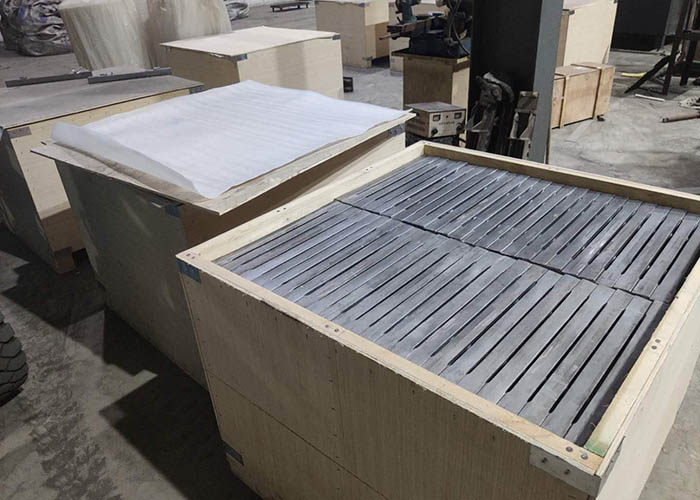

| Pasuru | Iron kesi kana Wooden kesi. |

Muhupfumi hwazvino hwekukwikwidza, kuchengetedza hunhu uku uchidzikisa mutengo kunogona kunetsa kune bhizinesi rega rega.

Asi kushandira pamwe nextj, haufanire kufunga nezvazvo. Tiri nyanzvi fekitari, yakananga wedzerai pashure kugadzirwa. Uye kune nyanzvi dzehunyanzvi vashandi uye mushure mekutengesa timu kukupa iwe nehunyanzvi masevhisi. Nenzira iyi, iwe unogona kuwana yakanakisa sevhisi iwe uchidzikisa mutengo.

Kune mimwe mibvunzo kana yehunyanzvi mibvunzo, ndapota nyorera XTJ Service Team. Isu tichapa iyo inonzwisisika mhinduro yehunyanzvi uye yakanyanya kunaka chitaurwa zvinoenderana nechigadzirwa chako.